All Optical Fiber Connector, Jumper,Pigtail Assemblies and Pre-terminated Closures, FAT Produced at Rayoptic Factory tested as IEC and Telcordia GR-326-Core,GR-3120-Core and GR-771-Core Standard.

Our engineer will test 10% samples taken from 353ND epoxy finished curing which filled in ferrule. Epoxy shall fully filled in ferrule and optical fiber enfolded by epoxy,no air holes.

Singlemode and Multimode Optical Fiber Connectors produced at Rayoptic factory shall be 100% tested IL and RL according the standard as below table.

| Ferrule Polish | Singlemode | Multimode | Standard | |||

| APC | UPC | PC | ||||

| Insertion Loss (dB) | Typical | Max. | Typical | Max. | 0.2 | IEC 61300-3-4 method B |

| 0.2 | 0.3 | 0.15 | 0.3 | |||

| 0.15 | 0.2 | 0.15 | 0.2 | NA | GR-326-Core Issue 4 | |

| Return Loss (dB) | >60 | >50 | NA | IEC 61300-3-6 method 1 | ||

| >65 | >55 | NA | GR-326-Core Issue 4 | |||

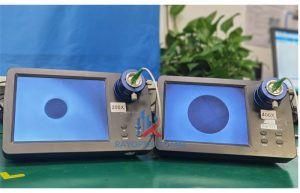

Singlemode and Multimode Optical Fiber Connectors produced at Rayoptic factory shall be 100% inspected ferrule polished endface and cleaning according the standard as below table.

Inspector Facility Magnification: 200X,400X

| Zone | Regions(µm) Singlemode | Regions(µm) Multimode | Scratches | Defects | Standard |

| A:Core | 0-25 | 0-65 | None | None | IEC 61300-3-35 |

| B:Cladding | 25-120 | 65-120 | None | None | |

| C:Adhesive | 120-130 | 120-130 | None | None | |

| D:Contact | 130-250 | 130-250 | None | None | |

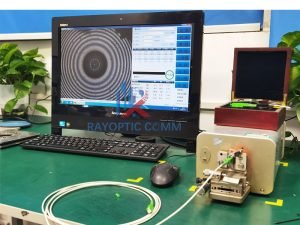

Normally, 3D Pass rate of optical fiber SM Connector Rayoptic Produced is ≥85%.

But more higher 3D pass rate:90%,100%, we also can supply and meet your high quality requirement.

| Parameters | APC IEC61755-3-2 GR-326-Core | UPC IEC61755-3-1 GR-326-Core |

| Radius of Curvature(mm) | 5 to 12 | 10 to 25 |

| Fiber Undercut and Protrusion(nm) | -100 to +100 | -100 to +100 |

| Apex Offset(µm) | 0 to 50 | 0 to 50 |

| Angle Error(°) | 8±0.3 | / |

| Key Error(°) | Min -0.5 Max. +0.5 | / |

Rayoptic engineer will do straight pull and 90° side pull test of optical fiber connector at the 10% sampling level in each order. We will make sure the connectors have good mechanical performance and do not lost function during installation.

| Parameters | Reinforced Connector | Conditions | Standard | Requirement |

| Straight Pull | SC FC LC ST MPO etc. (Mounted 1.6-2.0-3.0mm cable) | Magnitude of the force: 68N Speed: 5N/S Point of application : 0.5m of connector end Duration: 300s | IEC 61300-2-6 GR-326-Core Issue 4 4.4.3.4 | IL<0.3dB RL>50dB(UPC) ,>60dB (APC), |

| 90° Side Pull | Magnitude of the force: 34N Speed: 5N/S Point of application : 0.5m of connector end Duration: 300s | IEC 61300-2-42 GR-326-Core Issue 4 4.4.3.4 |

| Parameters | Reinforced Connector | Conditions | Standard | Requirement |

| Straight Pull | Hardened Connector serviced OSP | Magnitude of the force: 450N Speed: 5N/S Point of application : 0.5m of connector end Duration: 300s | IEC 61300-2-6 GR-3120-Core | IL<0.3dB RL>50dB(UPC) ,>60dB (APC), |

| 90° Side Pull | Magnitude of the force: 67N Speed: 5N/S Point of application : 0.5m of connector end Duration: 300s | IEC 61300-2-42 GR-3120-Core |

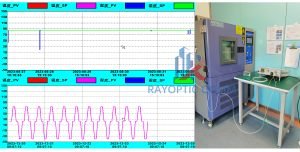

Beside mechanical test, thermal age and thermal cycle test are also essential measure that check the design of connector assembly and simulate the stresses that connector assemblies may be subjected to while in transportation and service.

| Test | Conditions | Standard | Requirement |

| Thermal Age Test | Temperature: 85℃ (185°F) Humidity: 85% RH Duration: 168 hours (7 days) | GR-326-Core Issue 4 4.4.2.1 | IL<0.3dB RL>50dB(UPC) ,>60dB (APC), |

| Thermal Cycle Test | Temperature: Cycle -40℃ to +75℃ Humidity: Uncontrolled Duration: 21 Cycles, 168 hours (7 days) | IEC 61300-2-22 GR-326-Core Issue 4 4.4.2.2 |

For the fiber optic connectivity products service at OSP and harsh environment,we will 100% test air tightness,such as Hardened Connector,Optical H Connector, MST’s terminals, Network Access Point (NAP) box, Fiber Distribution (CTO)Box, and Fiber Access Terminals(FAT) .

Overhead strand mount and pole mount installation,Ingress protection level at least upto IP67. Wall mount, pedestal and hand hole mount shall be upto IP68 protection level.

During FTTH broadband deployments, the pre-connectorized MST and OptiTap flat drop cable will be installed in manholes,handholes or vaults, so they must meet the IP68 protection rating. We believe that simulating the MST and drop cables being submerged in water by using a cylindrical water bucket is the most intuitive way to test their sealing performance.

We study the relevant standards GR-771 and GR-3120 and test our manufactured Pre-terminated closures and drop patch cables according to these standards. We only sell products that have been thoroughly verified.

With our expertise in fiber optic connectivity, we deliver reliable, scalable, and tailored solutions to help you stay ahead in a fast-moving market.

![]() 3F, Building E, Dahong Science Park,

3F, Building E, Dahong Science Park,

Baihua Community, Guangming District,

Shenzhen, Guangdong 518107, China

Copyright © 2026 Rayoptic Communication Co., Ltd. – Fiber Optic Connection All Rights Reserved.