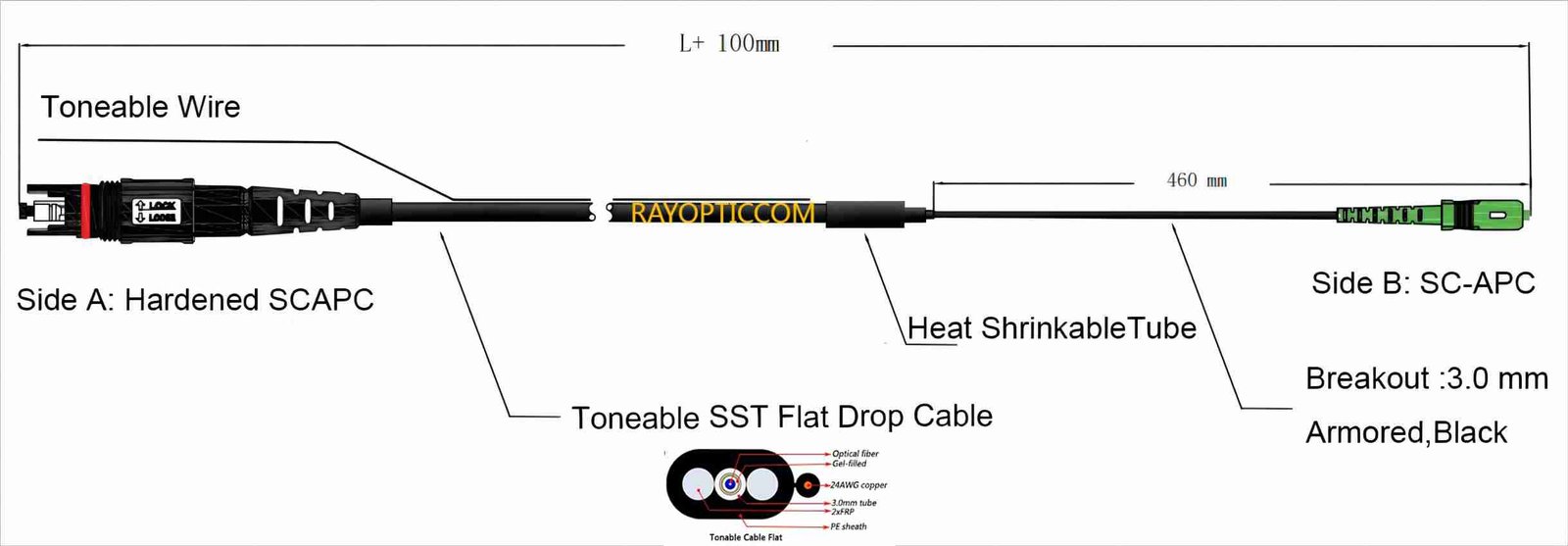

Hardened SCAPC to SCAPC Toneable Flat Drop Cable Fiber Optic Patchcord

Tags: SCAPC Connector,FTTH, FTTA, Optical toneable drop cable, Fiber optic drop cable, H connector, HOFC Connector, Fiber optic patch cord, Fiber Access Network, OSP Network, MST’s Terminals, MFT Box

Features

High quality

products are independently developed and produced, with good quality

IP68

waterproof test is done before each product is sold in order to ensure that each product meets the IP68 standard

Easy installation

The product is equipped with three kinds of installation accessories for different scenarios, easy operation and firm installation

Competitive price

independent production, easy to accept the price

Optical Parameters

Connector Insertion Loss(dB) Return Loss(dB)

@1310&1550nm @1310&1550nm

Hardened SCAPC Average≤0.20 ≥60

Max. ≤0.30

SCAPC Average≤0.20 ≥60

Max.≤0.30

Mechanical Parameters of Hardened Connector

| Item | Conditions | Test Method | Result |

Plug/Cap Straight pull(0°) | 100lbs(450N) for 60 seconds,wait 10 seconds and perform optical measurements | GR-3120-4.3.3 | Loss Increase <0.3dB |

Plug/Adapter Straight pull(0°) | 25lbs (112N) for 60 seconds,wait 10 seconds and perform optical measurements | GR-3120-4.3.3 | Loss Increase <0.3dB |

Plug/Adapter Side pull(90°) | 15lbs (67N) for 60 seconds,wait 10 seconds and perform optical measurements | GR-3120-4.3.3 | Loss Increase <0.3dB |

Transmission With Applied Tensile Load | 30 minutes @ 10lbs (45N): 23℃ at 0°, 90°, 135° degree angles | GR-3120-4.3.4 | Loss Increase <0.5dB |

Durability | 50 cycles, clean every 10 mating; @ 23℃Measurements @9,19,29,39,49 without cleaning. | GR-3120-4.3.5 | Insertion Loss <0.3 dB @1310&1550nm Return Loss ≥60 dB @1310&1550nm |

Environmental Parameters

Parameter Test Method Conditions

Temperature Change IEC61300-2-22 High Temperature: +75°C

GR-326-CORE Lowest Temperature: -40°C

168 Hours, 21 cycles

Ingress Protection IEC60529 IP68

(for Hardened Connector )

What is Hardened Fiber Optic Connector (HFOC) ?

A Hardened Fiber Optic Connector (HFOC) is a robust, durable type of fiber optic connector designed for use in harsh outdoor environments. These connectors are built to withstand extreme conditions, including temperature variations, moisture, dust, and physical stress. They are commonly used in applications such as Fiber to the Home (FTTH), Fiber to the Curb (FTTC), and other outdoor network deployments.

Key Features of Hardened Fiber Optic Connectors:

Durability:

- HFOCs are made with rugged materials that can resist physical damage and environmental stress, ensuring reliable performance in challenging conditions.

Weather Resistance:

- These connectors are typically sealed to protect against water, dust, and other contaminants. They often meet or exceed IP68 standards, which means they are dust-tight and can withstand continuous immersion in water.

Temperature Resistance:

- HFOCs are designed to operate across a wide temperature range, making them suitable for outdoor installations in various climates.

Easy Installation:

- Despite their ruggedness, HFOCs are designed for ease of use. They often feature simple push-pull or screw-type mechanisms for quick and secure connections without the need for specialized tools.

High Performance:

- HFOCs maintain high optical performance with low insertion loss and low back reflection, ensuring efficient and reliable data transmission.

Compatibility:

- These connectors are compatible with standard fiber optic cables and can be used in conjunction with other types of connectors and equipment in the network.

Common Applications:

Outdoor Networks:

- Used in outdoor fiber optic networks where cables need to be routed through environments exposed to the elements.

FTTH/FTTC:

- Essential for connecting homes or businesses to the main fiber optic network, particularly in last-mile connections.

Telecommunications Towers:

- Deployed in telecom towers and other infrastructure where reliable, high-performance connections are crucial despite environmental challenges.

Military and Industrial Applications:

- Suitable for use in military or industrial settings where equipment is subjected to harsh conditions and needs to maintain high reliability.

Example:

In an FTTH deployment, HFOCs might be used to connect the fiber optic cable from an outdoor distribution point to an Optical Network Terminal (ONT) located inside a customer’s home. The hardened connectors ensure that the connection remains stable and reliable despite exposure to weather and other environmental factors.

In summary, Hardened Fiber Optic Connectors (HFOCs) are designed to provide reliable, high-performance fiber optic connections in outdoor and harsh environments, ensuring network integrity and performance even under challenging conditions.