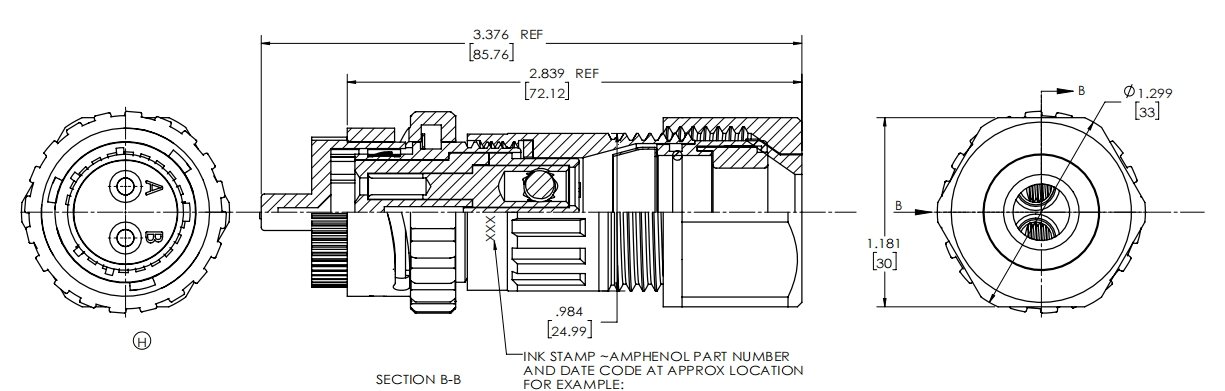

Ericsson Standard BTS 2 Way DC Power Cable Plug

Tags: RRU Remote Radio Unit, RRH Remote Radio Head, CPRI Common Public Radio Interface,RNT 447 32/02,RNT 447 31/03,RNT 447 30/02,RNT 447 24/001,RNT 447 32/03,RNT 447370/1,474282A APPB,474283A APPC

Features

- 60VDC&26A WITH HOT PLUG/40 A WITHOUT HOT PLUG

- STANDARD 2 TINES SOCKET

- SCREW FIELD INSTALLABLE

- WIRE 2,5-10MM² OR 10-16MM² WITH LARGER BACKSHELL

- CABLE SEALING OD FROM 6-18MM

- Circular connector, based on mil-c-26482;

- Bayonet locking mechanism, guarantees strong vibration and shock resistance;

- Tin over nickel plated finish version provides 360 degree EMI shielding with grounding fingers;

- Working temperature of -40c to + 120c;

- 30u’’ gold plated crimp contacts or silver plating depending current;

- Receptacles supplied with various termination version;

- Excellent lightning performance due to low resistance of the connector body;

- High salt spray resistance according to iso21207 method b5 ;

- IP67 rated in mated condition;

- Min 500 mating cycles guaranteed;

- Plugs use screw termination contacts for field installation;

Application

- RRU

- RRH

Specifications

Materials:

SHELL: ZINC ALLOY + TIN OVER NI PLATING

INSERT: PBT

CONTACT: COPPER ALLOY + SILVER PLATING

SCREW/WAVED WASHER/SHIELDING RING: STAINLESS STEEL

EMI STRIP: COPPER ALLOY + NICKEL PLATING

GASKET/SLEEVE/ORING: SILICONE RUBBER

COUPLING NUT: NYLON

RUBBER SLEEVE OF COUPLING NUT: EPDM

HEX NUT/CABLE GLAND BODY: PA66

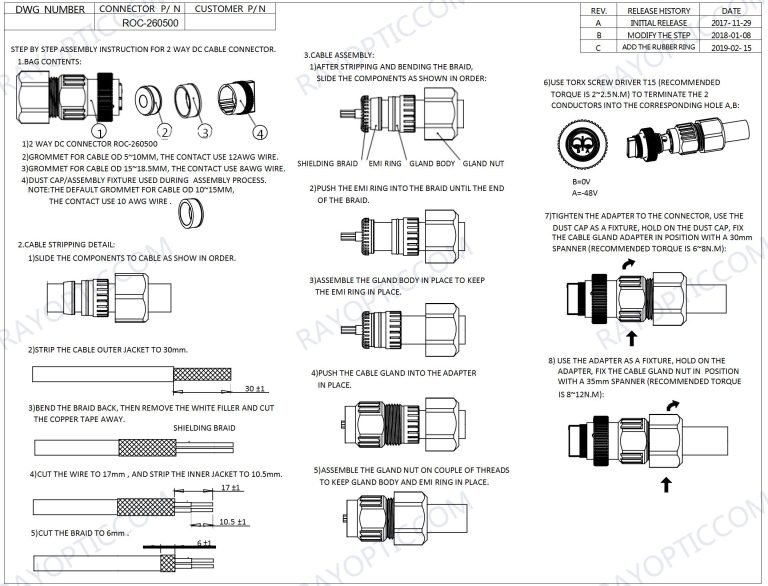

User Manual

What is A Standard BTS DC Power Connector ?

A standard BTS (Base Transceiver Station) DC power connector is a specialized connector used to supply direct current (DC) power to the BTS equipment. These connectors are designed to handle the high current and voltage requirements of BTS installations and are typically robust, weather-resistant, and easy to connect and disconnect. Here’s an overview of what constitutes a standard BTS DC power connector:

Key Features of BTS DC Power Connectors

High Current and Voltage Ratings:

- Designed to handle the substantial power requirements of BTS equipment, typically supporting high current (in the range of tens to hundreds of amperes) and voltage (usually 48V DC, which is standard in telecom applications).

Durability and Reliability:

- Constructed to withstand harsh environmental conditions, including extreme temperatures, humidity, and physical stress. Often made of materials that resist corrosion and wear.

Safety Features:

- Includes features to prevent accidental disconnection and ensure secure connections, such as locking mechanisms and keyed designs to prevent incorrect insertion.

Ease of Use:

- Designed for quick and easy installation, often with tool-less connectors that can be connected and disconnected without the need for specialized tools.

Compatibility:

- Standardized to ensure compatibility with a wide range of BTS equipment from different manufacturers. This includes standard sizes and pin configurations.

Common Types of BTS DC Power Connectors

Anderson Powerpole Connectors:

- Modular and stackable connectors that are widely used in telecom and other high-power applications. Known for their versatility and ease of use.

Amphenol Connectors:

- Provides a range of ruggedized power connectors designed for telecom applications, including BTS installations. Known for their durability and reliability.

Positronic Power Connectors:

- High-reliability connectors used in various critical applications, including telecom. They offer high current capacity and robust construction.

HARTING Han® Connectors:

- Industrial connectors that are robust and suitable for outdoor and harsh environments. Often used in BTS and other telecom infrastructure.

Assembly and Installation

Preparation:

- Ensure the power is turned off before starting the installation to avoid electrical hazards.

- Verify the connector type and ensure it matches the BTS equipment and power supply specifications.

Cable Preparation:

- Strip the outer insulation of the power cables, and strip the ends of the inner conductors to expose the wire.

- Ensure the cable ends are clean and free from damage.

Connector Assembly:

- Attach the cable conductors to the connector terminals. This may involve crimping or soldering, depending on the connector type.

- For crimp connectors, use the appropriate crimping tool to ensure a secure connection.

- For solder connectors, use a soldering iron to attach the wires securely.

Securing the Connection:

- Insert the assembled connector into the BTS power input port. Ensure it is fully seated and locked in place if the connector has a locking mechanism.

- Check the connection to ensure it is secure and there are no loose wires.

Testing:

- Once the connection is made, power on the system and use a multimeter to check for correct voltage and current.

- Verify that the BTS equipment is receiving power and operating correctly.

Maintenance and Troubleshooting

- Regular Inspections:

- Periodically inspect the connectors and cables for signs of wear, damage, or corrosion. Replace any damaged components promptly.

- Cleaning:

- Keep the connectors clean and free from debris. Use appropriate cleaning tools and methods.

- Testing:

- Regularly test the connectors with a multimeter to ensure proper electrical continuity and performance.

Conclusion

A standard BTS DC power connector is a critical component in ensuring the reliable operation of telecom infrastructure. These connectors are designed for high power capacity, durability, and ease of use, making them suitable for the demanding environment of BTS installations. Proper assembly, installation, and maintenance of these connectors are essential for maintaining continuous and efficient network operations.