MPO/MTP® patch cable assemblies have moved from “nice to have” to “default choice” in many high-density environments—especially modern data centers and large-scale network upgrades. As bandwidth requirements rise and rack density increases, MPO/MTP connectivity helps simplify cable management, accelerate deployment, and support scalable migration paths for parallel optics.

At Rayoptic, we manufacture MPO/MTP fiber optic patch cable assemblies with a strong focus on three fundamentals:

Connector brand options (Senko, US Conec, Xiayu)

UL OFNP-certified cable materials (plenum-rated)

Documented pre-shipment inspection and testing, including end-face + geometry verification, polarity checks, and IL/RL test records

This article explains why demand is surging, what the market outlook suggests for the next three years, and how Rayoptic builds trust into every shipment.

1) Why Demand for MPO/MTP Assemblies Is Growing So Fast

AI data centers and cloud expansion are driving higher bandwidth and density

AI training and inference clusters generate massive east–west traffic, pushing data center networks toward faster, higher-density optical interconnects. This shift increases demand for multi-fiber connectivity solutions that support parallel optics and structured cabling workflows—where MPO/MTP trunk, harness, and patch assemblies are widely used.

Market research consistently points to AI and cloud growth as major drivers for fiber connectivity demand. For example, Grand View Research highlights cloud computing and AI as key growth factors in the fiber optic connectors market outlook.

Projects are shifting from field termination to factory pre-termination

Data center projects increasingly prioritize repeatable performance and fast installation. Factory pre-terminated MPO/MTP assemblies reduce on-site variability and can shorten deployment timelines—especially when combined with standardized patching and panel/cassette architectures.

Compliance and safety requirements are rising—UL OFNP matters more often

In many building and data center environments, plenum spaces (air-handling spaces) may require plenum-rated cabling. OFNP (Optical Fiber Nonconductive Plenum) is commonly used for these areas and is designed to meet fire-resistance and low-smoke requirements.

3-Year Market Outlook (2026–2028): What to Expect

It’s difficult to forecast one single number for MPO/MTP assemblies specifically (because reports segment the market differently), but multiple credible signals suggest continued growth:

Fiber optic connectors market: Grand View Research estimates USD 5.56B in 2024 and projects USD 9.93B by 2033, with a 6.6% CAGR (2025–2033).

MPO fiber optic connector segment: Valuates estimates USD 831M in 2024 and forecasts ~USD 2.005B by 2031, with a 13.6% CAGR (2025–2031).

What that means for the next three years:

If the broader connector market grows around 6–7% annually and MPO-related segments grow around 13–14% annually, then over a 3-year window (2026–2028), the cumulative growth implied is roughly ~20% (at ~6.6% CAGR) up to ~45–50% (at ~13.6% CAGR), depending on product mix and application demand.

In practical terms, customers will likely continue emphasizing:

High-density structured cabling readiness

Consistent, documented optical performance

Traceability (labeling, SN/lot control)

Compliance-ready cable material options (e.g., UL OFNP)

2) Rayoptic MPO/MTP Patch Cable Assemblies: Connector Brand Options

Different projects have different requirements. Some specify premium brands; others need a qualified, cost-effective solution aligned to defined performance targets. Rayoptic supports multiple connector brand options:

Senko MPO (including MPO-PLUS® ecosystem options)

Selected for stable performance and consistent end-face quality in demanding deployments.US Conec MTP®

A widely recognized option in high-density structured cabling environments and commonly specified for data center projects.Xiayu (China local brand)

A cost-effective option for projects that prioritize value while still meeting defined inspection and test requirements.

We support common assembly formats including MPO/MTP patch cords, trunk cables, and harness/breakout assemblies, with configuration options based on fiber count, polarity method, length, and loss targets.

3) UL OFNP Cable Materials (Plenum Rated)

Rayoptic can use fiber optic cable materials with UL OFNP certification, supporting customer requirements for plenum applications and compliance documentation. OFNP is designed for use in ducts and plenum air-handling spaces and is associated with fire-resistant and low-smoke characteristics.

For customers, using UL OFNP-certified cable materials can help:

Simplify project compliance review

Reduce uncertainty during site acceptance

Improve traceability through consistent cable marking and documentation

4) Rayoptic Pre-Shipment Quality Control: What We Check (and the Reference Standards)

Rayoptic can provide a structured pre-shipment QC workflow and inspection report to verify products are deploy-ready.

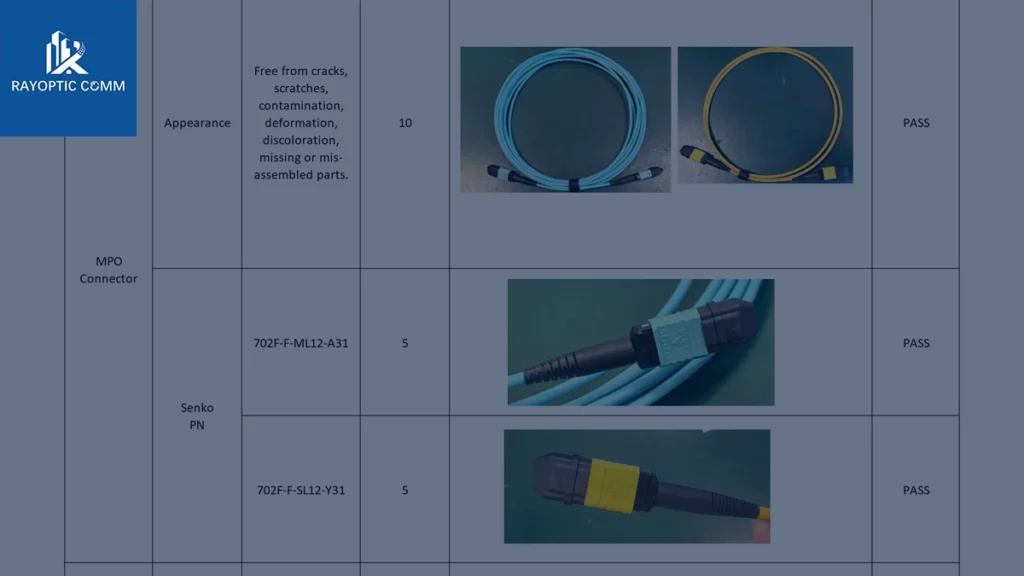

Process #1 — Visual & Configuration Check (Appearance + Length + Marking)

We verify:

No cracks, scratches, contamination, deformation, discoloration, missing or mis-assembled parts

Correct cable marking and color

Length verification (end-to-end)

UL OFNP cable confirmation (as required by the order)

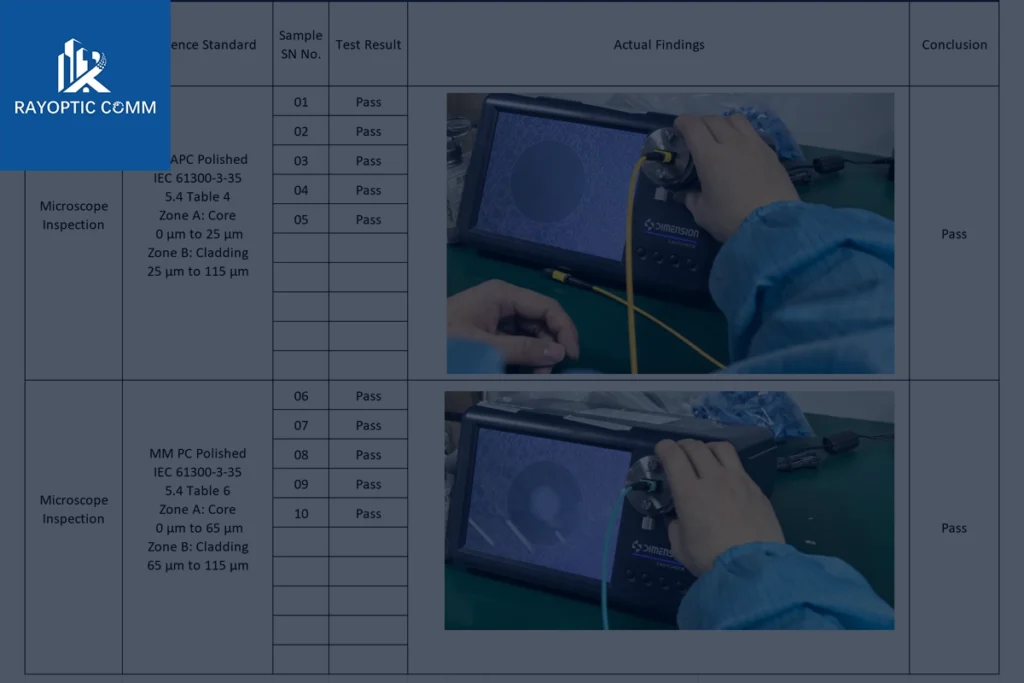

Process #2 — End-Face Check (Microscope + Geometry Verification)

End-face quality is critical for stable IL/RL results and long-term performance. Before IL/RL testing, Rayoptic performs a two-step end-face verification:

A) Microscope Inspection (Cleanliness & Defect Check)

Reference standard: IEC 61300-3-35

Zone-based acceptance criteria (as applied in your report):

Single-mode (SM, APC polished): Zone A (Core) 0–25 μm, Zone B (Cladding) 25–115 μm

Multimode (MM, PC polished): Zone A (Core) 0–65 μm, Zone B (Cladding) 65–115 μm

If contamination is found, we clean and re-check before moving forward.

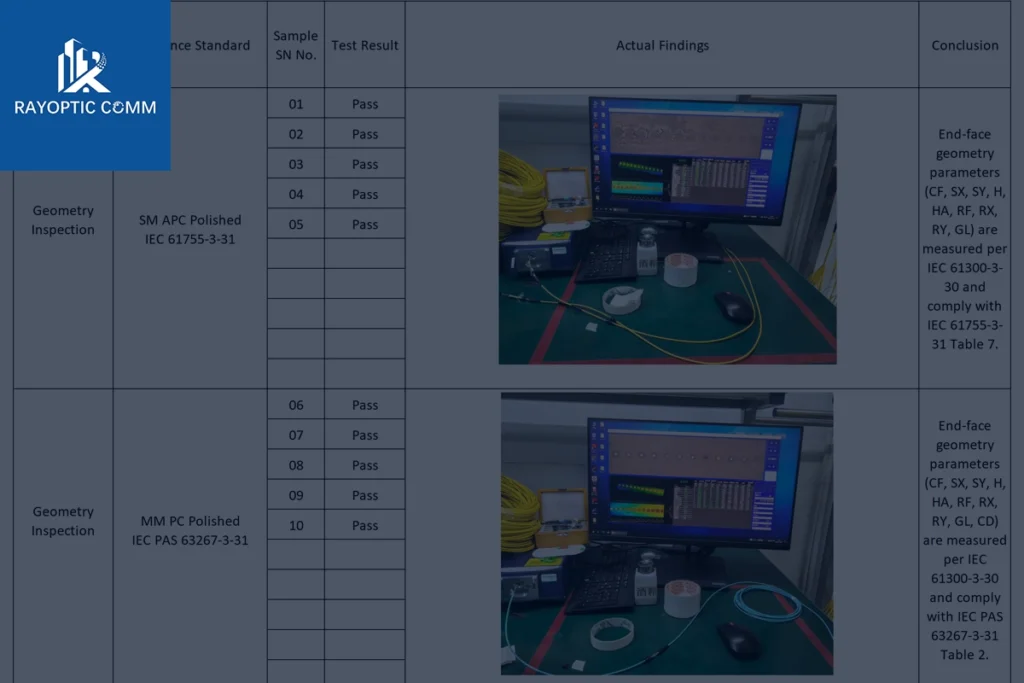

B) Geometry Inspection (Interferometer Measurement)

Measurement method: IEC 61300-3-30

Geometry parameters measured (examples): ROC/RF (radius of curvature), RX/RY (apex offset), H (fiber height), HA (ferrule angle), etc.

Acceptance criteria:

SM APC polished: compliant with IEC 61755-3-31 (applicable table limits)

MM PC polished: compliant with IEC PAS 63267-3-31 (applicable table limits)

Only assemblies that pass both microscope and geometry inspection proceed to IL/RL testing.

Process #3 — Polarity Verification (e.g., Type B)

We confirm polarity configuration according to the customer requirement. Industry guidance emphasizes selecting one polarity method and maintaining consistency across the installation; TIA standards describe multiple polarity methods and their interoperability considerations.

Process #4 — Optical Performance (IL/RL by Channel)

We test and record:

Insertion Loss (IL) and Return Loss (RL) by channel

Min/Max/Average results in the inspection record

Typical method references used in industry practice include IEC 61300 series test methods for IL/RL.

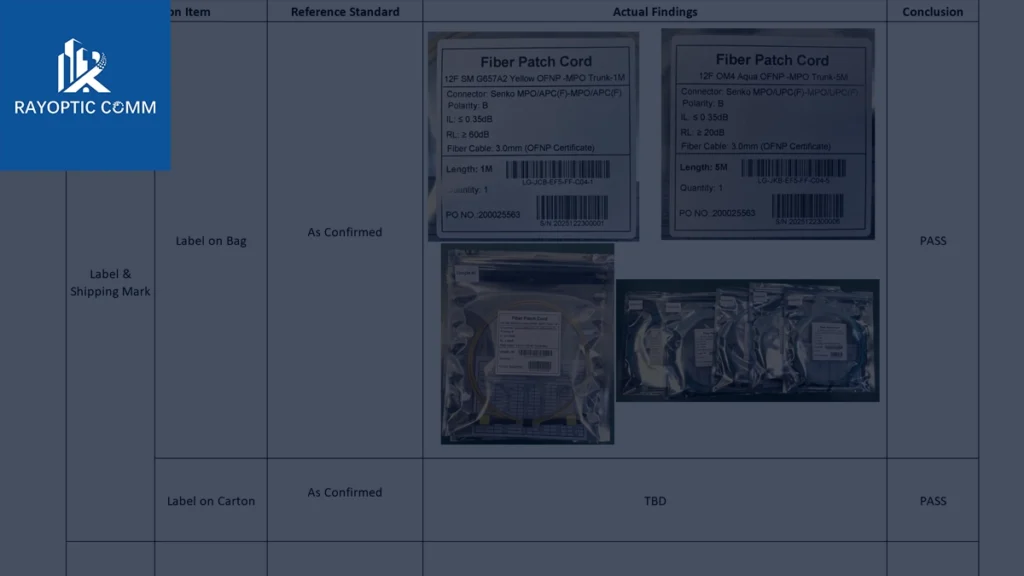

Process #5 — Packaging + Labeling Verification

We verify:

Bag label content: PN, length, fiber type, polarity, IL/RL requirement, SN/barcode

Carton label and shipping marks (as confirmed)

Packaging protection integrity for transit and warehouse management

Final Takeaway: What Customers Should Look for in an MPO/MTP Supplier

For most data center and structured cabling customers, supplier selection often comes down to three practical questions:

Are connector options available to match project specs (brand, performance, consistency)?

Are cable materials compliance-ready and traceable (e.g., UL OFNP for plenum needs)?

Is pre-shipment QC documented in a way that’s verifiable (end-face + geometry + polarity + IL/RL)?

Rayoptic supports MPO/MTP patch, trunk, and harness assemblies with connector brand options, UL OFNP cable materials, and documented pre-shipment QC so customers can deploy with confidence.

Contact Rayoptic: sales@rocfttx.com

If you share your fiber count, polarity method, length, and IL/RL targets, we can recommend a suitable configuration and provide a sample inspection report for evaluation.